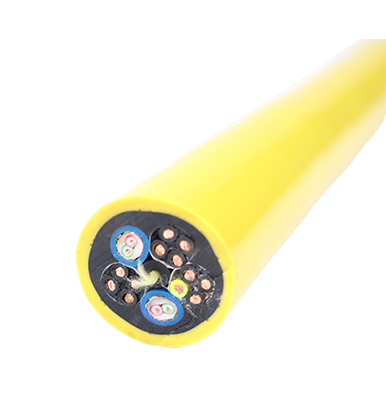

The PVC Reel Cable is designed to provide durable and flexible power and control signal transmission in industrial, commercial, and mobile applications. Engineered with high-quality copper conductors and PVC insulation, these cables ensure stable performance under mechanical stress, frequent bending, and harsh environmental conditions.

Widely used in factory automation, machinery, control panels, construction equipment, and mobile systems, PVC Reel Cables offer ease of installation, long-term reliability, and compliance with international standards such as IEC, UL, and RoHS.

PVC Reel Cables are built for dynamic applications where frequent winding and unwinding on reels is required. Their flexible construction and robust insulation make them ideal for continuous motion systems and mobile equipment.

Conductors: High-purity copper (Class 5 or 6) for superior electrical conductivity.

PVC Insulation: Provides thermal, chemical, and mechanical protection.

Outer PVC Jacket: Resistant to abrasion, oil, UV, and mechanical impact.

Optional Shielding: Foil or braided shielding for EMI/RFI protection.

Flexible Design: Maintains integrity during repeated bending and reel operation.

| Feature | Description | Benefit |

|---|---|---|

| High Flexibility | Designed for continuous flexing on reels | Reduces wear and prolongs cable life |

| Durable Construction | Resistant to oil, abrasion, UV, and chemicals | Long-term reliability in industrial environments |

| High Conductivity | Copper conductors | Efficient power and signal transmission |

| Optional Shielding | Prevents electromagnetic interference | Ensures accurate signal control |

| Global Compliance | IEC, UL, RoHS certified | Safe and internationally recognized |

| Ease of Installation | Reel-ready design | Simplifies deployment in machinery and automation systems |

PVC Reel Cables are suitable for industrial, commercial, and mobile applications:

Factory Automation: Powering motors, sensors, and actuators.

Machinery and Equipment: CNC machines, conveyor systems, and robotic arms.

Control Panels: Distribution of power and control signals.

Mobile Equipment: Cranes, forklifts, and construction vehicles.

Renewable Energy Systems: Flexible connections for solar panels and wind turbines.

Material Handling: Automated storage and retrieval systems.

| Parameter | Specification |

|---|---|

| Conductor Material | Annealed copper (Class 5 or 6) |

| Insulation Material | PVC |

| Rated Voltage | 300/500V, 450/750V, 0.6/1kV |

| Conductor Size | 0.5 mm² – 35 mm² |

| Number of Cores | 1 to 61 cores (customizable) |

| Operating Temperature | -15°C to +70°C |

| Minimum Bending Radius | 5–6 × cable diameter |

| Shielding | Optional foil or braided |

| Flame Retardancy | IEC 60332-1 compliant |

| Standards | IEC 60227 / IEC 60502 / UL 62 |

| Certifications | CE, RoHS, ISO 9001 |

Proper inspection ensures that PVC Reel Cables perform reliably and safely in industrial applications.

Check the outer jacket for cuts, abrasions, or discoloration.

Inspect conductor ends and connectors for corrosion or loose connections.

Ensure reels are free from tangles or kinks.

| Test | Purpose | Standard Reference |

|---|---|---|

| Insulation Resistance Test | Verify insulation integrity | IEC 60227, UL 62 |

| Continuity Test | Confirm conductor connection | IEC 60332-1 |

| Voltage Test | Ensure rated voltage tolerance | IEC 60502 |

| Flexibility Test | Assess performance under repeated bending | IEC 60227 |

Visual Inspection: Every 3–6 months

Electrical Testing: Annually

Connector and Termination Check: Every 6 months

PVC Reel Cables must be operated following standard guidelines to ensure safe and efficient performance:

Verify that the cable’s voltage and current rating matches system requirements.

Maintain the minimum bending radius to prevent conductor damage.

Avoid placing cables near sharp edges or high-temperature surfaces.

Separate power and control cables to reduce electromagnetic interference.

Wind and unwind cables slowly and evenly to prevent tangling.

Avoid over-stretching the cable during reel operation.

Ensure reels rotate freely without obstruction.

Use strain reliefs at termination points to reduce mechanical stress.

Regular maintenance improves cable life and operational reliability.

| Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Every 3–6 months | Check for cuts, abrasions, or discoloration |

| Electrical Testing | Annually | Insulation resistance and continuity tests |

| Connector Check | Every 6 months | Tighten terminals, inspect for corrosion |

| Cleaning | As needed | Remove dust, oil, and debris from outer jacket |

Avoid sharp bends and kinking.

Protect cables from chemical exposure and extreme temperatures.

Ensure proper storage after use to maintain natural coil shape.

Use strain reliefs at all terminations.

Correct storage ensures long-term performance:

Keep cables in cool, dry, and ventilated areas.

Avoid direct sunlight, moisture, or extreme heat.

Store reels upright and prevent stacking heavy objects.

Protect cables from chemicals and mechanical damage.

Secure reels to prevent movement and impact during transport.

Protect cables from moisture, UV exposure, and sharp objects.

Include labels, inspection certificates, and test reports for verification.

Flexible and Durable: Maintains performance under continuous flexing and reel operation.

Reliable Electrical Transmission: Ensures stable power and control signals.

Easy Installation: Reel-ready design reduces setup time.

Global Standard Compliance: IEC, UL, RoHS certified for safety and international use.

Long Service Life: Resistant to oil, abrasion, chemicals, and UV exposure.

Energy Efficient: High-conductivity copper reduces power loss.

The PVC Reel Cable is a versatile and high-performance solution for industrial, commercial, and mobile applications requiring flexible, durable, and reliable power and signal transmission.

With premium copper conductors, PVC insulation, optional shielding, and compliance with international standards, it ensures safe and efficient operation in dynamic and harsh environments. Proper inspection, maintenance, operation, and storage practices extend cable life and performance, making PVC Reel Cables a trusted choice for engineers, project managers, and industrial system integrators worldwide.

This website uses cookies to ensure you get the best experience on our website.