In modern industrial environments, Automation Reel Cables play a crucial role in providing reliable power and control signal transmission for automated systems. These cables are engineered with high-quality copper conductors, durable insulation, and flexible design, allowing them to withstand continuous movement, mechanical stress, and harsh industrial conditions.

Widely used in robotic arms, conveyor systems, assembly lines, and factory automation, Automation Reel Cables ensure stable, precise, and energy-efficient operation. They comply with international standards such as IEC, UL, and RoHS, making them suitable for global industrial applications.

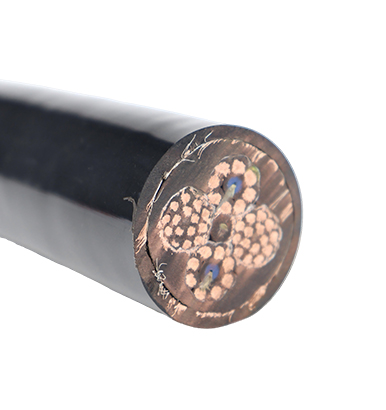

An Automation Reel Cable is a type of flexible multi-core or single-core cable designed for use with reel systems in automated machinery. Its primary purpose is to transmit power and control signals while allowing for smooth movement and repeated winding and unwinding on cable reels.

Conductors: High-purity copper (Class 5) for superior electrical conductivity.

Insulation: PVC, XLPE, or EPR for thermal, mechanical, and chemical protection.

Outer Sheath: Resistant to abrasion, oil, UV, and mechanical stress.

Optional Shielding: Foil or braided shields to prevent electromagnetic interference (EMI).

Flexible Design: Ensures longevity under continuous flexing and reel operation.

| Feature | Description | Benefit |

|---|---|---|

| Flexibility | Designed for constant movement on reels | Reduces fatigue and prolongs cable life |

| High Conductivity | Copper conductors with low resistance | Stable and efficient power transmission |

| Durability | Resistant to abrasion, oil, chemicals, and UV | Suitable for industrial environments |

| EMI Protection | Optional shielding layer | Ensures accurate signal transmission in noisy areas |

| Energy Efficient | Low resistance and optimized design | Reduces energy loss in industrial systems |

| Compliance | IEC, UL, RoHS certified | Safe and globally accepted for automation projects |

| Easy Installation | Reel-ready design | Simplifies deployment in automated machinery |

Automation Reel Cables are designed for dynamic industrial applications:

Robotics: Powering and controlling robotic arms in assembly lines.

Conveyor Systems: Supplying electricity and signals to moving conveyors.

Factory Automation: Connecting PLCs, actuators, sensors, and motors.

Automated Warehouses: Powering retrieval and storage systems.

Packaging Machinery: Ensuring continuous operation in dynamic machinery.

Automotive Manufacturing: Supporting moving production equipment and assembly lines.

| Parameter | Specification |

|---|---|

| Conductor Material | Annealed copper (Class 5) |

| Insulation Material | PVC, XLPE, EPR |

| Rated Voltage | 300/500V, 450/750V, 0.6/1kV |

| Number of Cores | 2 to 61 cores (customizable) |

| Conductor Size | 0.5 mm² – 35 mm² |

| Operating Temperature | -15°C to +70°C |

| Bending Radius | 5–6 × cable diameter |

| Shielding | Optional foil or braided |

| Flame Retardancy | IEC 60332-1 compliant |

| Standards | IEC 60227 / IEC 60502 / UL 62 |

| Certifications | CE, RoHS, ISO 9001 |

Providing reliable after-sales service ensures the long-term performance of Automation Reel Cables.

Standard warranty covers manufacturing defects and performance failures.

Replacement or repair is offered for defective cables within the warranty period.

Pre-sale consultation for cable selection and configuration.

Installation guidance and troubleshooting support for reel systems.

Assistance with maintenance schedules and energy optimization.

Supply of reel adapters, connectors, and protective sheaths.

Customized cable solutions for unique industrial setups.

Proper operation of Automation Reel Cables ensures performance, safety, and longevity.

Ensure the cable is compatible with the reel’s maximum bending radius.

Maintain proper tension to avoid kinking or over-stretching.

Separate power and control cables to minimize electromagnetic interference.

Avoid placing cables near sharp edges or hot surfaces.

Verify that the cable’s voltage and current ratings match system requirements.

Use strain reliefs at terminations to reduce mechanical stress.

Avoid twisting or tangling during winding and unwinding.

Ensure reels rotate freely without obstruction to prevent cable damage.

Automation Reel Cables require careful handling to maximize safety and performance:

| Precaution | Reason | Action |

|---|---|---|

| Avoid sharp bends | Reduces risk of conductor breakage | Follow minimum bending radius guidelines |

| Prevent overloading | Protects insulation and conductors | Ensure current rating is not exceeded |

| Keep away from chemicals | Prevents insulation degradation | Store and operate in clean environments |

| Avoid excessive tension | Prevents mechanical stress | Use proper cable routing and strain reliefs |

| Check reel alignment | Prevents uneven winding | Inspect reels regularly during operation |

Automation Reel Cables are designed to minimize energy loss and comply with modern industrial energy standards:

Low Conductor Resistance: Reduces voltage drop and energy wastage.

Optimized Multi-Core Design: Efficient transmission of multiple circuits.

RoHS Compliance: Environmentally friendly materials reduce carbon footprint.

Flame Retardant and Durable Materials: Reduces energy required for replacements and maintenance.

Proper maintenance prolongs cable life and ensures continuous operation of automated systems:

| Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Every 3–6 months | Check for abrasion, cuts, or insulation damage |

| Electrical Testing | Annually | Verify continuity, insulation resistance, and voltage drop |

| Connector Inspection | Every 6 months | Ensure tight connections and check for corrosion |

| Cleaning | As needed | Wipe outer sheath to remove dust, oil, or debris |

Avoid over-stretching or twisting cables.

Do not expose cables to excessive heat or chemicals.

Apply strain reliefs at all connection points.

Keep cables away from moving machinery that could cause wear.

Durable and Flexible: Handles continuous motion in reel systems.

Reliable Signal Transmission: Optional shielding reduces EMI/RFI interference.

Energy Efficient: Low resistance reduces power loss.

Compliance: Meets IEC, UL, and RoHS standards for global projects.

Simplified Installation: Reel-ready design reduces setup time.

Comprehensive Support: After-sales, maintenance, and technical guidance provided.

The Automation Reel Cable is an essential solution for modern industrial automation, offering durable, flexible, and energy-efficient power and control transmission.

With high-quality conductors, robust insulation, optional shielding, and compliance with international standards, it ensures stable operation in dynamic machinery and reel systems. Proper installation, maintenance, and after-sales support further enhance performance and longevity.

Automation Reel Cables provide cost-effective, reliable, and environmentally friendly solutions for engineers, system integrators, and project managers worldwide.

This website uses cookies to ensure you get the best experience on our website.